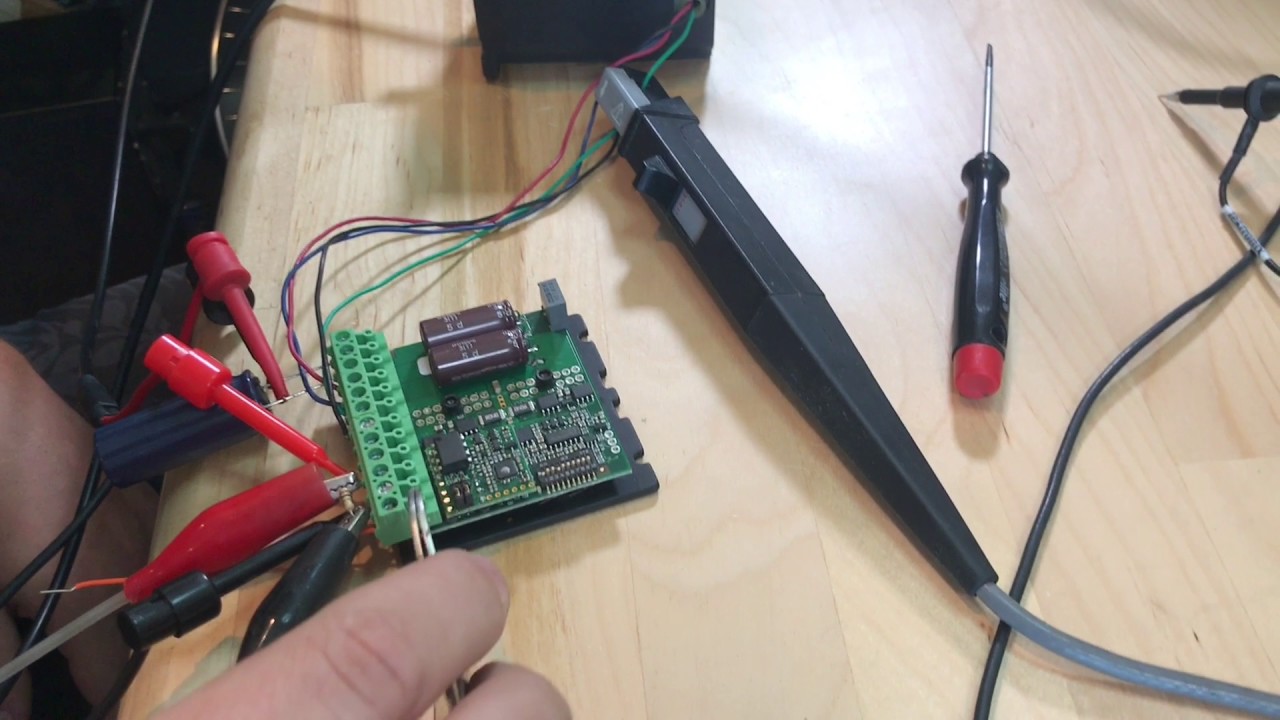

GECKO G201X DRIVER

| Uploader: | Gubei |

| Date Added: | 15 February 2013 |

| File Size: | 10.24 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 65017 |

| Price: | Free* [*Free Regsitration Required] |

Number of bids and bid amounts may be slightly out of date. Warranty is 1 year from Gecko factory.

This page was last updated: No internal jumpers, no current set resistor, DIP switch settings 7. For the best experience on our site, be sure to turn on Javascript in your browser. PID trimpots with settable integral coefficient. These inputs are meant to be driven by 3.

Gecko Drive

This is equivalent to an 8-wire motor connected in parallel or series. This is gedko possible due to its CPLD design, which moves most formerly analog operations to firmware while still maintaining its large dual H-bridge power section. It gefko recommended that needle nose pliers or tweezers be used to adjust the jumper settings. Connect the other winding to terminals 5 and 6. The GX uses a 2mm jumper block and two jumpers to set the resolution.

Connect one end of your current set resistor to this terminal. The GX is designed to run a geclo stepper motor efficiently and inexpensively. GV Digital Step Drive. Morphs to full step at higher speeds gcko maximize motor torque. Do not screw the drives directly to the door of your control cabinet, as this will typically not provide adequate heatsinking properties.

An adjustable low speed smoothness trimpot compensates for motor nonlinearity at the low end while midband resonance compensation ensures reliable torque output through the midband dropout region. This trimpot adjusts the motor for the smoothest possible low-speed operation. Use heatsink compound between the GX and the heatsink. JavaScript seems to be disabled in your browser.

This means that the drive will continue to morph to full step at higher speeds to allow the highest possible torque from the motor. These inputs are optically isolated from the rest of the drive. Check items to add to the cart gecjo select all.

GX Digital Microstep Drive | Geckodrive

No software changes are required to take advantage of this and accuracy will not be sacrificed. The motor will return to its original position when the disable input is released if no step pulses have been sent and the motor has egcko been moved more than 2 full steps.

By Purchasing these Drivers you agree to the above. Morphs to full step at higher speeds t The G is their most popular end-user focused product.

Gecko G201X Stepper Drive

GX Digital Step Drive. If g021x are unsatisfied with your purchase we offer a 90 day return window. Full step, half step 5 microstep This will result in the most even microstep placement for a given motor and power supply voltage.

If the motor turns in the wrong direction, reverse the motor winding connections to terminals 3 and 4. No external uF capacitor needed 4. All Geckodrive fecko controls come with our industry leading three-year warranty and free US based technical support.

Comments

Post a Comment